Hardcase

The Direct Filling Technology uses a volumetric dosing pump, a switch valve to select vacuum, inert gas or rinsing solvent and a filling valve that directly connects the dosing pump via a short filling stud tightly to the filling hole of the hard case cell. No pre-chamber is used. Alternatively the filling valve can connect the switch valve supply to the cell.

Patent pending DE 10 2022 128 101.9 - Title “Direct fill technology“

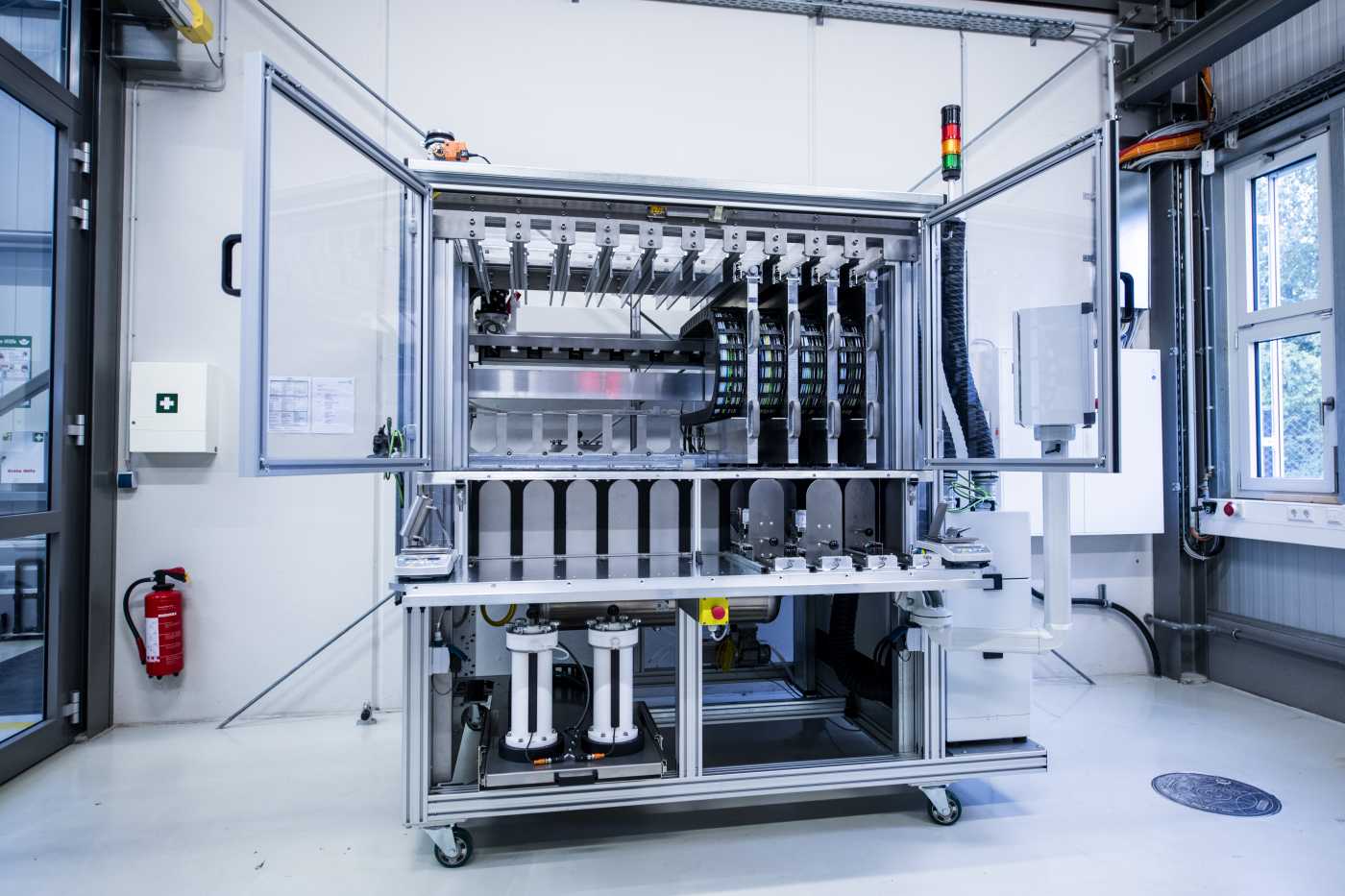

Electrolyte Injector - from research and development to fully automatic production

The Electrolyte Injector brings the advantages of the Direct Filling Technology into your cell production.

This machine can easily be adapted to produce cylindrical and prismatic cells. It is designed modular so the machine can be generated according to your demand:

- Stainless steel frame assembled from standard beams and connecting cubes form segments

- Similar basic segments can accommodate filling Units, media tanks and distribution, control and interfaces, soaking devices, plugging stations and many more

- Machine frame variants for dry room: manual loading or for robot loading: glove box

- Dosing stations are available with different max. filling pressures: Standard 6 bars, High Pressure 20 bars or even 40 bars with IP PS Cell Protection (patent pending)

- Filling units can be combined out of different dosing and cell stations to customer’s needs

- Filling is always automatic

- The Electrolyte Injector can be expanded later on by further filling stations or by complete segments

- Atmosphere control of the ATEX areas

- Full traceability of the filled cells and its parameters, rejects are notified and sorted out

Advantages over previous technologies:

- Fast filling - up to 4 times faster

- Precise filling - up to 5 times more accurate

- Safe filling - less reject rate

- Clean filling - makes cell washing an unnecessary expense